PROXXON LATHE

PLEASE NOTE THESE TOOLS WILL TAKE 7-10 DAYS DELIVERY TO OUR STORE

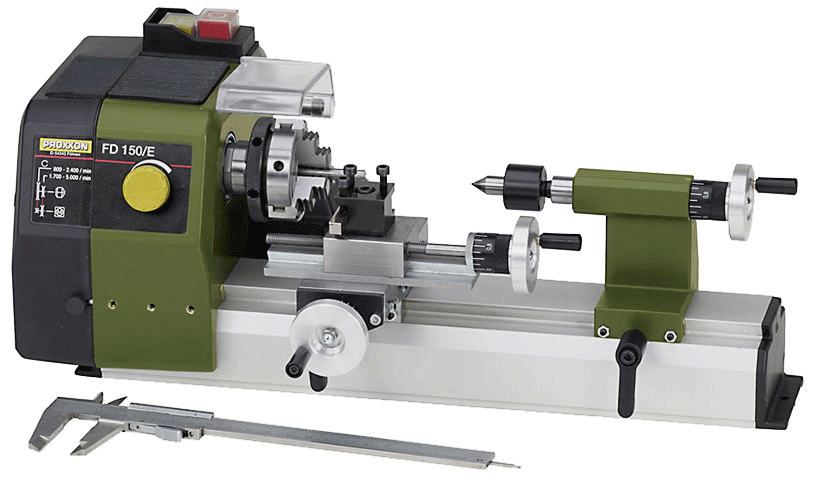

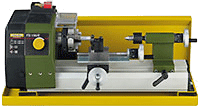

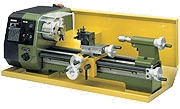

Precision lathe FD 150/E

2-stage belt drive and additional electronic control enables spindle speeds up to 5,000rpm. The right cutting speed for even the smallest pieces. For face turning, longitudinal turning, boring, taper turning, slicing and drilling. Complete with 3-jaw chuck and live centre. Centre distance 150mm. Swing 55mm. Height over cross slide 33mm.

Machine bed with dovetail guides of continuous casting aluminium.

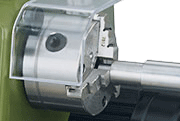

Die-cast aluminium spindle headstock. With quiet special DC motor, 2-stage belt drive and additional electronic speed control for high engine power at low speeds for larger work pieces and for the appropriate cutting speed, even for the smallest pieces. Main switch with emergency stop function and restart protection. Precision bearing mounted main spindle with continuous 8.5mm bore. Chuck fit for standard ER 11 type collets.

Three-jaw chuck, self-centering. Inside jaws 1.5 - 32mm, outside jaws 20 - 50mm.

Die-cast aluminium tailstock with spindle and live centre (fitting MK 0/ short).

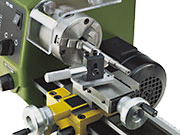

Support: To be shifted manually on the bed and clamped with lever. Rotating tool post for turning steels 6 x 6mm. Processing via top slide (60mm, travel distance Z) and cross slide (40mm, travel distance X). The angle adjustment of the upper carriage makes it possible to turn tapers up to +/- 45°.

Handwheels with zero adjustable scale ring (1 division = 0.05mm, 1 revolution = 1mm).

Other technical data:

230V. 50/60Hz. Distance between centres 150mm. Swing 55mm. Height over cross slide 33mm. Cross slide travel (X) 40mm, top slide travel (Z) 60mm. Steel tool post for turning steels 6 x 6mm. Spindle bore 8.5mm. 2-stage belt drive with electronic speed control: Stage 1 = 800 - 2,800rpm. Stage 2 = 1,500 - 5,000rpm. Dimensions approx. 360 x 150 x 150mm. Weight 4.5kg. Insulated to class 1.

NO 24 150

Accessories for the FD 150/E

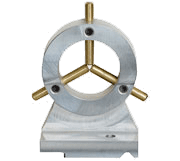

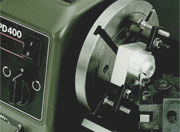

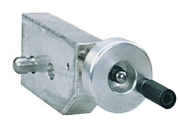

Radius cutting attachment

Radius cutting attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

NO 24 062

Chip collecting tray with splash guard for the FD 150/E

Chip collecting tray with splash guard for the FD 150/E

Of 1.5mm thick sheet steel, powder-coated. Bevelled edges at the front and back enable easy cleaning. Pre-drilled mounting holes for the secure stability of the FD 150/E. L 400 x W 165 x H 140mm. The lathe depicted here is not included in the scope of delivery.

NO 24 156

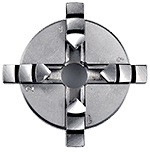

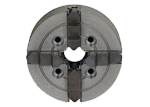

4-jaw-chuck, self-centering

4-jaw-chuck, self-centering

Used to clamp cylindrical, square or octagonal work pieces. High accuracy. Clamping range with reversible jaws from 2 - 20mm (inside) and 20 - 50mm (outside). Ø 50mm.

NO 24 158

Drill chuck. Capacity 0.5 - 6.5mm.

Drill chuck. Capacity 0.5 - 6.5mm.

Industrial quality with high concentricity (allowed up to 10,000rpm). Complete with arbour B 10 x MK 0/short. For the tailstock of the FD 150/E.

NO 24 152

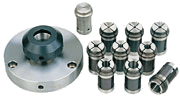

Multiple range standard ER 11 type collets

Multiple range standard ER 11 type collets

Offering high concentricity. May be reduced up to 0.5mm below their nominal diameter (intermediate sizes not required). D = 11.5mm, L = 18mm. One each of 2 - 2.5 - 3 - 4 - 5 - 6 and 7mm are included. With clamping nut M 16 x 1. Suitable for the main spindle of the FD 150/E. Supplied in a wooden box.

NO 24 154

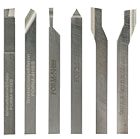

6-piece turning tool set. Made of high-quality cobalt HSS steel. Ground.

6-piece turning tool set. Made of high-quality cobalt HSS steel. Ground.

One each boring, roughing out, parting, finishing, right and left cutter. Size 6 x 6 x 65mm. For FD 150/E, supplied in wooden box.

NO 24 524

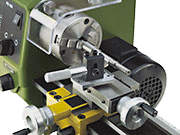

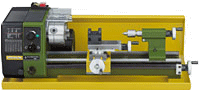

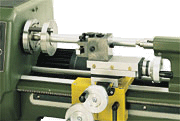

Precision lathe PD 250/E

For face, longitudinal and taper turning, thread-cutting.

For machining steel, brass, aluminium and plastic.

Mounting flange for fastening the mill/drill head PF 230.

Centre distance 250mm. Swing 70mm. Height over cross slide 43mm.

Machine bed: Of cast iron, wide-legged prismatic guide. For vibration-free work even at high loads. Rear flange for mounting the mill/drill head PF 230. Covered lead spindle.

Headstock: Of die-cast aluminium. Precision bearing mounted main spindle (run-out without chuck 1/100mm) with 10.5mm opening. Chuck side 70mm hollowed to 14mm. With MK 2 bore. Rotary switch for engaging the automatic feed via lead and feed spindle (optionally 0.05 or 0.1mm/rev.).

Tailstock: Of die-cast aluminium. Sleeve Ø 18mm, retractable up to 30mm. With millimetre scale, MK 1 bore and live centre.

Support: Bed carriage made of die-cast zinc. Cross slide and top slide of steel (adjustment 60 or 45mm). Turning tool post for cutting tools size 8 x 8mm.

Drive: Quiet DC special motor with 3-stage belt drive for 300 - 900 and 3,000rpm. With additional speed control (full-wave electronics) continuously adjustable to 100 - 300 or 1,000rpm, depending on belt ratio. Clockwise - anticlockwise rotation. Main switch with emergency stop function and restart protection.

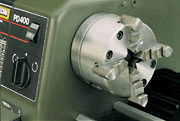

Lathe chuck: High quality 3-jaw chuck as per DIN 8386 Class 1 (concentricity tolerance 0.04mm). Capacity through reversing jaws from 2 - 75mm. Including lathe chuck guard with safety shutdown.

Handwheels: Of aluminium, with adjustable scale ring (1 division = 0.05mm, 1 revolution = 1mm).

Thread cutting device: With change gears for left-hand and righthand threads of the most important metric pitches (0.5 - 0.625 - 0.7 - 0.75 - 0.8 - 1 - 1.25 - 1.5mm).

Other technical data: 230V. 50/60Hz. Size L 560, W 270, H 170mm. Weight approx. 12kg.

NO 24 002

Accessories for the PD 250/E

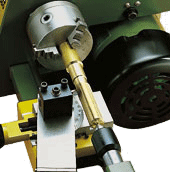

Radius cutting attachment

Radius cutting attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

NO 24 062

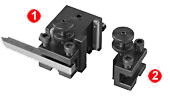

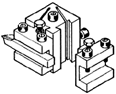

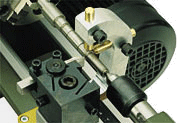

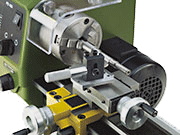

![]() Quick change tool post - easy to use!

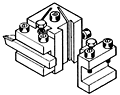

Quick change tool post - easy to use!

For quick tool change and easy height adjustment. Includes 2 tool holder elements.

NO 24 026![]() Additional quick change tool holder (separately)

Additional quick change tool holder (separately)

Can be used with the above above-mentioned quick change tool post.

NO 24 024

Chip collecting tray with splash guard

Chip collecting tray with splash guard

Made from 1.5mm thick sheet metal, powder coated. Bevelled edges at the front and back allow slight clean-ing. Mounting hole and raised base to secure lathe are pre-drilled. L 550 x W 240 x H 160mm. The depicted lathe is not included in the offer.

NO 24 008

4-jaw chuck with independent jaws

4-jaw chuck with independent jaws

For clamping angular and asymmetrically shaped work pieces. Capacity up to 80mm. Chuck Ø 75mm.

NO 24 036

Collet set with ER 20 collets:

Collet set with ER 20 collets:

For extreme true concentric accuracy. 2 - 10mm.

For high precision machining of round parts. The collet set is mounted instead of the lathe chuck. With 8 collets (2 - 2.5 - 3 - 4 - 5 - 6 - 8 and 10mm). Packed in a wooden box.

NO 24 038

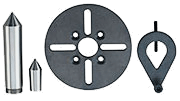

Centre turning attachment.

Centre turning attachment.

For highest accuracy with high rotational precision.

This includes: 1 face plate, 2 fixed centres (MK 2 and MK 1/short) and 1 drive dog. Packed in a wooden box.

NO 24 014

Fixed steady for longer work pieces

Fixed steady for longer work pieces

Especially for boring. Also required if the tailstock cannot be used to "counter". Up to Ø 40mm.

NO 24 010

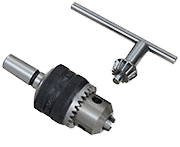

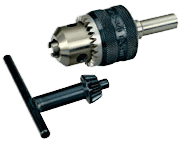

Professional gear chuck with MK 1

Professional gear chuck with MK 1

For the tailstock of the PD 250/E. Capacity up to 10mm.

NO 24 020

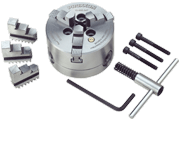

Self-centering 3-jaw chuck

Self-centering 3-jaw chuck

Identical to chuck of lathe PD 250/E. High quality clamping fixture as per DIN 8386, Class 1 (concentricity accuracy 0.04mm). Capacity through reversing jaws from 2 - 75mm. Suitable for PD 250/E and the dividing attachment NO 24 044.

NO 24 034

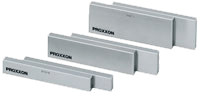

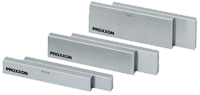

14-piece parallel supports set

14-piece parallel supports set

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.02mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

NO 24 266

Cutting tools of high quality cobalt HSS steel, ground  Five piece set

Five piece set

One each roughing out, parting, finishing cut, left and right cutter. Comes in wooden box with sliding lid. 8 x 8 x 80mm.

NO 24 530

Three piece thread cutting set

Three piece thread cutting set

One cutter for ![]() external thread (ground to 60°, metric) one for

external thread (ground to 60°, metric) one for ![]() internal thread, one

internal thread, one ![]() general cutting. Comes in wooden box with sliding lid. 8 x 8 x 80mm.

general cutting. Comes in wooden box with sliding lid. 8 x 8 x 80mm.

NO 24 540

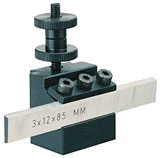

Parting tool holder and tool

Parting tool holder and tool

Used in the PD 250/E quick change system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt. Spare tools available under NO 24 554.

NO 24 217

Spare tool for parting tool holder (not depicted)

As described above.

NO 24 554

Cutter set with tungsten inserts

Cutter set with tungsten inserts

Three holders (90mm long):![]() for roughing out;

for roughing out;![]() for longitudinal work;

for longitudinal work;![]() for 90mm boring bar, holes from 12mm.

for 90mm boring bar, holes from 12mm.

Standard tungsten inserts, 55°, plated (commercially available version). Three additional inserts securing screw and key TX 8 are included. 8 x 8mm.

NO 24 555

Tungsten disposable tips (not depicted)

For the holders as described above.

NO 24 557Ten piece set

Offset cutter set with carbide inserts

Offset cutter set with carbide inserts

Holder angled to the left by 45° for cylindrical carbide inserts Ø 6mm. For extra high surface quality and low surface roughness, for turning radii and cutting round grooves. Set includes two tungsten inserts, two insert securing screws and TX 8 key.

NO 24 5608 x 8 x 60mm

Carbide inserts (not depicted)

For the holder as described above.

NO 24 56410 pieces

Three piece centre drill set

Three piece centre drill set

Made of HSS steel. DIN 333 (type A) 60°. Complete set centre drills with sizes of 2 - 2.5 and 3.15mm.

NO 24 630

HSS boring tool set, 6 pieces

HSS boring tool set, 6 pieces

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 1.3mm - 2.65mm and 4mm. Shaft of Ø 6mm. Length 95mm. The cutters are held by a tool holder (9 x 9mm) that mounts to the tool post of either PD 230/E, PD 250/E or PD 400. Comes in wooden box with sliding lid.

NO 24 520

Tool holder for rotary tools.

Tool holder for rotary tools.

For use on lathe machines.

Made of steel with standard 20mm MICROMOT collar size. For precise clamping of rotary tool IBS/E or LBS/E in the tool post of the lathe. Shaft 8 x 10mm. Total length 65mm.

NO 24 098

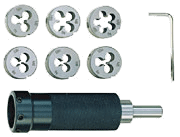

Die holder for round dies

Die holder for round dies

For threads M 3 - 4 - 5 - 6 - 8 and 10. With holder Ø 10mm for mounting in the tailstock drill chuck of the lathe. The holder is held by hand while cutting the threads. Neatly packed in wooden box with sliding lid.

NO 24 082

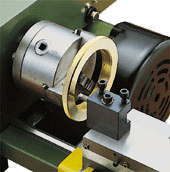

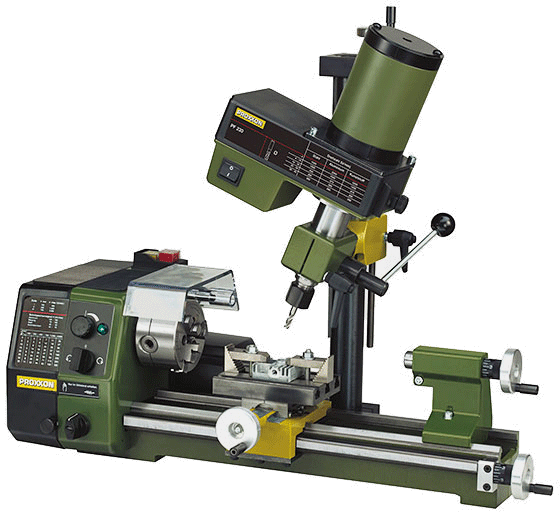

Mill and drill head PF 230

Converts your lathe PD 250/E or PD 400 into a complete machining centre.

Incudes column (35 x 400mm), mounting bracket and fastening screws (the PD 250/E and PD 400 already come with a plane-milled surface). The lathe's top slide is replaced with the table (supplied) of 110 x 70mm, with 3 T-slots 12 x 6 x 5mm. The lathe now functions as a compound table, with X-Y travel being longitudinally and cross-wise respectively. The mill/drill head is identical to the MICRO miller FF 230. Three collets of sizes 6 - 8 and 10mm are included.

NO 24 104

Note:

Lathe not included.

Accessories for the PF 230

Fine feed for milling machine PF 230

Fine feed for milling machine PF 230

Easily installed in a few seconds. The feed may be used via either the height feed (vertical) or the fine feed in the tilted position. The graduated scale may be zero reset. One revolution is equivalent to 1.5mm spindle travel (1 division = 0.05mm).

NO 24 140

Gear tooth chuck (10mm) with adapter

Gear tooth chuck (10mm) with adapter

Industrial quality, however not as accurate as the collets. With 10mm adapter which fits into the 10mm collet. Includes the chuck key.

NO 24 110

Five piece collet set (not depicted)

Includes 1 each of 2.4 - 3 - 3.2 - 4 and 5mm, for milling cutters. Supplied in a wooden box with sliding lid.

NO 24 144

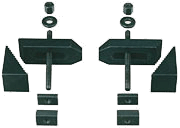

Step clamp set of steel.

Step clamp set of steel.

2 step blocks and clamps each.

With matching slot nuts and fastening screws for T-slots as per MICROMOT standard (12 x 6 x 5mm). In wooden box with sliding lid.

NO 24 256 For work pieces up to 20mm thickness

NO 24 257 For work pieces up to 35mm thickness

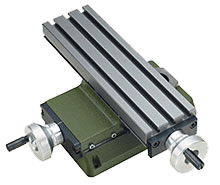

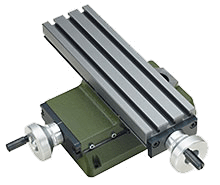

Compound table KT 230

Compound table KT 230

As described at MICRO miller FF 230 and FF 250/BL, but excluding headstock and column. With 34mm bore to mount the PF 230 and PF 250/BL mill/drill head (the end fitting of the mill head's 35mm column is machined to 34mm).

NO 24 106

Milling cutter set (2 - 5mm)

Milling cutter set (2 - 5mm)

All cutters with 6mm shaft. Cutters of Ø 2 - 3 - 4 and 5mm. Double fluted according to DIN 327. Made of HSS-Co5. Supplied in wooden box with sliding lid.

NO 24 610

Milling cutter set (6 - 10mm)

Milling cutter set (6 - 10mm)

4 cutters Ø 6 - 7 - 8 and 10mm. Four flute design according to DIN 844. Shafts 6 and 10mm respectively. Made of HSS-Co5. Supplied in wooden box with sliding lid.

NO 24 620

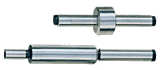

Edge finder set

Edge finder set

Used for fast and accurate location of starting point of work pieces with respect to the machine spindle on milling machines. Size 6 x 6 x 50mm and 6 x 5 x 75mm. Comes in wooden box with sliding lid.

NO 24 434

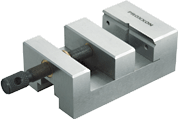

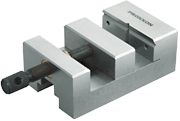

Precision vice PM 60

Precision vice PM 60

Jaw width 60mm. Clamping capacity 42mm. Total length 100mm.

NO 24 255

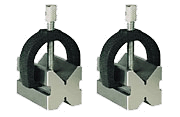

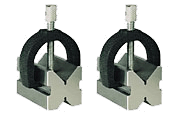

Precision V-blocks

Precision V-blocks

Used to clamp various work pieces.

Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

NO 24 262 2 pieces

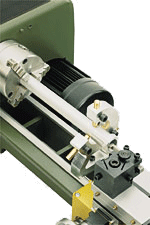

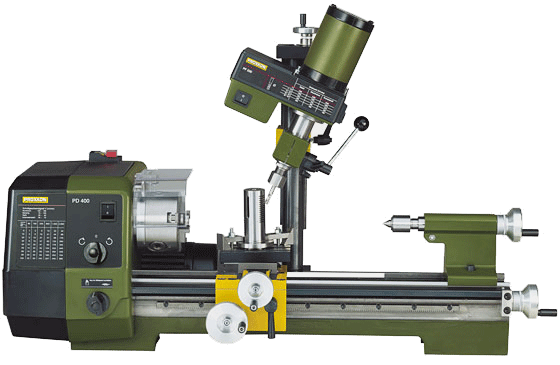

Precision lathe PD 400

Centre distance 400mm. Swing 85mm. Height over cross slide 58mm. For machining steel, brass, aluminium and plastic. For face and straight turning, taper turning and thread cutting. With an extensive range of system accessories you can also drill, mill and slot.

NO 24 400

- Main switch with auto-start protection and emergency off.

- Precision lathe chuck as per DIN 6386 (Ø 100mm).

- Quick-change tool post with 2 holders (with stop and height adjustability).

- With rotating centre MK 2 and tailstock chuck.

- Aluminium handwheels with adjustable graduated collar made from steel.

- Switch for clockwise, off and counter-clockwise rotation.

- Selector for auto-feed.

- Handwheel for quick adjustment of the support.

- Cross-braced cast iron bed, wide-legged shape, and prism slides for apron and tailstock.

- Protected lead screw with 12 x 1.5 Acme thread.

Note:

The lathe PD 400 is also available as CNC version (PD 400/CNC) with recirculating ball spindles, step motors and user-friendly WINDOWS-compatible software.

Machine bed: Of high quality cross-braced cast iron with wide-legged, prism slides. For vibration-free work even at high loads. With flange and threaded holes at back for fastening the drill and mill head PF 230. Covered lead spindle.

Headstock: Of die-cast aluminium. Oversized main spindle with two adjustable taper roller bearings and MK 3 bore on chuck side. Spindle bore 20.5mm. Run-out without chuck 1/100mm. Rotary switch for engaging the automatic feed (optionally 0.07 and 0.14mm/rev.). Lead and feed spindle with trapezoid threading (12 x 1.5mm).

Tailstock: Of die-cast aluminium. Sleeve Ø 24mm, retractable up to 40mm. With mm scale. With live centre MK 2 and 10mm gear tooth chuck (B 12 - bore/MK 2).

Support: Bed carriage made of die-cast zinc. Cross slide (adjustment 85mm) and top slide (setting range 52mm) of steel. Top slide can be swivelled for taper turning (degree graduation up to 45° available). With multiple tool posts and two tool post elements for quick change and easy height adjustment. For turning tools 10 x 10mm.

Drive: Powerful capacitor motor for two speeds and additional threestage belt drive. Spindle speeds at stage 1: 80 - 330 - 1,400rpm. For stage 2: 160 - 660 and 2,800rpm.

Lathe chuck: High quality 3-jaw chuck as per DIN 6386 Class 1 (concentricity tolerance 0.04mm). Capacity through reversing chucks 3 - 100mm. Including lathe chuck guard with safety shutdown.

Handwheels: Of aluminium, with scale ring adjustable to 0. For cross slide and top slide: 1 division = 0.025mm. 1 rev. = 1mm. For tailstock and lead spindle: 1 graduation line = 0.05mm. 1 rev. = 1.5mm.

Support quick adjustment: By means of large handwheel fastened to bed by toothed rack.

Thread cutting device: For left-hand and right-hand thread. With change gears for 19 different metric pitches: 0.2 - 0.25 - 0.3 - 0.35 - 0.4 - 0.45 - 0.5 - 0.6 - 0.7 - 0.75 - 0.8 - 0.9 - 1 - 1.25 - 1.5 - 1.75 - 2 - 2.5 - 3mm. Also for inch threads from 10 - 48TPI.

Other technical data:

230V. 50/60Hz. Size L 900, W 400, H 300mm. Weight approx. 45kg. Motor rated input 870W, power output 550W, motor speeds 1,400 / 2,800rpm. A tool holder with two adjustable inserts is included as standard.

A tool holder with two adjustable inserts is included as standard.

Accessories for the PD 400

Splash guard and chip collecting tray for lathe PD 400

Splash guard and chip collecting tray for lathe PD 400

Made from 1.5mm steel plate, powder coated. A welded cover protects the motor. Mounting holes and raised base to secure the lathe are pre-drilled. Seeping through of coolant is impossible. Length 800 x width 270 x height 290mm.

NO 24 402

Note:

The lathe depicted here is not included.

Self-centering 3-jaw chuck

Self-centering 3-jaw chuck

Identical to the lathe chuck of lathe PD 400. Capacity through reversing chucks 3 - 100mm.

NO 24 407

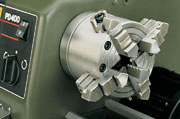

Self-centering 4-jaw chuck

Self-centering 4-jaw chuck

The jaws are not independently adjustable, i.e. they are self-centering. High accuracy. Chuck diameter 100mm.

NO 24 408

4 jaw chuck with independent jaws

4 jaw chuck with independent jaws

Used to mount irregularly and asymmetrically shaped objects. Each jaw is adjusted individually and centering is thus achieved manually. Hardened, reversible jaws. Chuck diameter 100mm.

NO 24 410

Faceplate and clamps

Faceplate and clamps

Is fitted instead of the standard chuck. Ideal for clamping larger and asymmetrically shaped work pieces. Ø 125 mm. 2 continuous T-slots. With clamping jaws.

NO 24 412

Collet attachment with collets for PD 400

Collet attachment with collets for PD 400

For accurate use on round components. One hardened collet each hardened collet 2 - 3 - 4 - 5 - 6 - 8 - 10 - 12 and 14mm are included. Concentric accuracy better than 0.02mm, much better than a chuck. One soft collet for making a custom size yourself. The included collet attachment is mounted in the place of the headstock chuck. Supplied in a wooden box.

NO 24 419 complete

Centre turning accessory for PD 400

Centre turning accessory for PD 400

Ideal when turning with highest possible accuracy. Supplied with 2 dead centres (MK2 and MK3), drive/ face plate with 30mm bore as well as reducing bushes 30/20mm and 30/15mm. A threaded drive pin screws into the headstock flange and the drive plate.

NO 24 414

Fixed steady to support longer pieces for PD 400

Fixed steady to support longer pieces for PD 400

Used on the PD 400 when turning long, slender work pieces. Fitted directly to the bed-ways and is used when the tailstock support is inadequate. Maximum Ø 50mm.

NO 24 404

Travelling steady for PD 400

Travelling steady for PD 400

Fitted to the carriage of the lathe. Indispensable when turning long, slender work pieces. Maximum Ø 50mm.

NO 24 406

Radius cutting attachment

Radius cutting attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

NO 24 062

Tool post

Tool post

Including two holders. Provides quick tool changes with easy height adjustment. For turning tools 10 x 10mm.

NO 24 415

Cutting tools of high quality cobalt HSS steel, ground. Five piece set

Five piece set

One each roughing out, parting, finishing cut, left and right cutter. Comes in wooden box with sliding lid. 10 x 10 x 80mm.

NO 24 550

Three piece thread cutting set

Three piece thread cutting set

One cutter for external thread ![]() , one for internal thread

, one for internal thread ![]() (both ground to 60°, metric), one general cutting

(both ground to 60°, metric), one general cutting ![]() . Supplied in wooden box with sliding lid. 10 x 10 x 80mm.

. Supplied in wooden box with sliding lid. 10 x 10 x 80mm.

NO 24 552

Cutter set with tungsten inserts

Cutter set with tungsten inserts

Three holders (90mm long):![]() for roughing out;

for roughing out;![]() for longitudinal work;

for longitudinal work;![]() for 90mm boring bar, holes from 12mm.

for 90mm boring bar, holes from 12mm.

Standard tungsten inserts, 55°, plated (commercially available version). Three additional inserts securing screw and key TX 8 are included. 10 x 10mm.

NO 24 556 complete

Offset cutter set with carbide inserts

Offset cutter set with carbide inserts

Holder angled to the left by 45° for cylindrical carbide inserts Ø 6mm. For extra high surface quality and low surface roughness, for turning radii and cutting round grooves. Set includes two tungsten inserts, two insert securing screws and TX 8 key.

NO 24 56210 x 10 x 70mm

Carbide inserts (not depicted)

For the holders as described above.

NO 24 56410 pieces

Parting tool holder and tool

Parting tool holder and tool

Used in the PD 400 quickchange system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt.

NO 24 417

Spare tool for parting tool holder

As described above.

NO 24 554

Three piece centre drill set

Three piece centre drill set

Made of HSS steel. DIN 333 (type A) 60°. Complete set centre drills with sizes of 2.0 - 2.5 and 3.15mm.

NO 24 630

HSS boring tool set, 6 pieces

HSS boring tool set, 6 pieces

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 1.3mm - 2.65mm and 4mm. Shaft of Ø 6mm. Length 95mm. The cutters are held by a tool holder (9 x 9mm) that mounts to the tool post of either PD 230/E, PD 250/E or PD 400. Comes in wooden box with sliding lid.

NO 24 520

Tool holder for rotary tools.

Tool holder for rotary tools.

For use on lathe machines.

Made of steel with standard 20mm MICROMOT collar size. For precise clamping of rotary tool IBS/E or LBS/E in the tool post of the lathe. Shaft 8 x 10mm. Total length 65mm.

NO 24 098

14-piece parallel supports set

14-piece parallel supports set

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.02mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

NO 24 266

Mill/drill head PF 230

for lathe PD 400

Incudes column (35 x 400mm), mounting bracket and fastening screws. For mounting on the PD 400. The lathe's top slide is replaced with the table (supplied) of 110 x 70mm, with 3 T-slots 12 x 6 x 5mm. The lathe now functions as a compound table, with X-Y travel being longitudinally and cross-wise respectively. The mill/drill head is identical to the miller FF 230. Three collets of sizes 6 - 8 and 10mm are included.

NO 24 104

Note:

Lathe, milling cutters, work clamps and blocks not included in system.

Accessories for the mill/drill PF 230

Fine feed for milling machine PF 230 and MICRO miller FF 230

Fine feed for milling machine PF 230 and MICRO miller FF 230

Easily installed in a few seconds. The feed may be used via either the height feed (vertical) or the fine feed in the tilted position. The graduated scale may be zero reset. One revolution is equivalent to 1.5mm spindle travel (1 division = 0.05mm).

NO 24 140

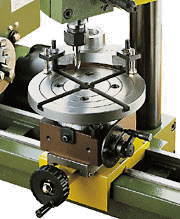

Universal dividing table UT 400

Universal dividing table UT 400

For accurate machining of circular work pieces. The table may be fixed horizontally or vertically. Worm drive for division through 360° allowing for almost all possible divisions below 100. Supplied with 4 index plates: 27/42, 33/40, 34/39 and 36/38. Used to manufacture sprockets, gearboxes and drives, ratchets, cams, etc. (the faceplate is not included). The taper is identical to the main spindle of the lathe. With matching nuts and screws for fixation in MICROMOT standard T-slots (12 x 6 x 5mm). Supplied in a wooden box with sliding lid.

NO 24 421

Gear tooth chuck (10mm) with adapter

Gear tooth chuck (10mm) with adapter

Industrial quality, however not as accurate as the collets. With 10mm adapter which fits into the 10mm collet. Includes the chuck key.

NO 24 110

Five piece collet set for PF 230 and FF 230 (not depicted)

Includes 1 each of 2.4 - 3 - 3.2 - 4 and 5mm, for milling cutters. Supplied in a wooden box with sliding lid.

NO 24 144

Precision vice PM 60

Precision vice PM 60

Perfectly rectangular. To be placed sideways and on the end face. With matching nuts and screws for fixation in MICROMOT standard T-slots (12 x 6 x 5mm). Supplied in wooden box with sliding lid. Jaw width 60mm. Clamping capacity 42mm. Total length 100mm.

NO 24 255

Precision V-blocks

Precision V-blocks

Used to clamp various work pieces. Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

NO 24 262 2 pieces

Milling cutter set (2 - 5mm)

Milling cutter set (2 - 5mm)

All cutters with 6mm shaft. Cutters of Ø 2 - 3 - 4 and 5mm. Double fluted according to DIN 327. Made of HSS-Co5. Comes in wooden box with sliding lid.

NO 24 610

Milling cutter set (6 - 10mm)

Milling cutter set (6 - 10mm)

4 cutters Ø 6 - 7 - 8 and 10mm. Four flute design according to DIN 844. Shafts 6 and 10mm respectively. Made of HSS-Co5. Comes in wooden box with sliding lid.

NO 24 620

Edge finder set

Edge finder set

Used for fast and accurate location of starting point of work pieces with respect to the machine spindle on milling machines. Size 6 x 6 x 50mm and 6 x 5 x 75mm. Comes in wooden box with sliding lid.

NO 24 434

Compound table KT 230

Compound table KT 230